## Chúng Tôi Đã “Mổ Xẻ” iPhone 16

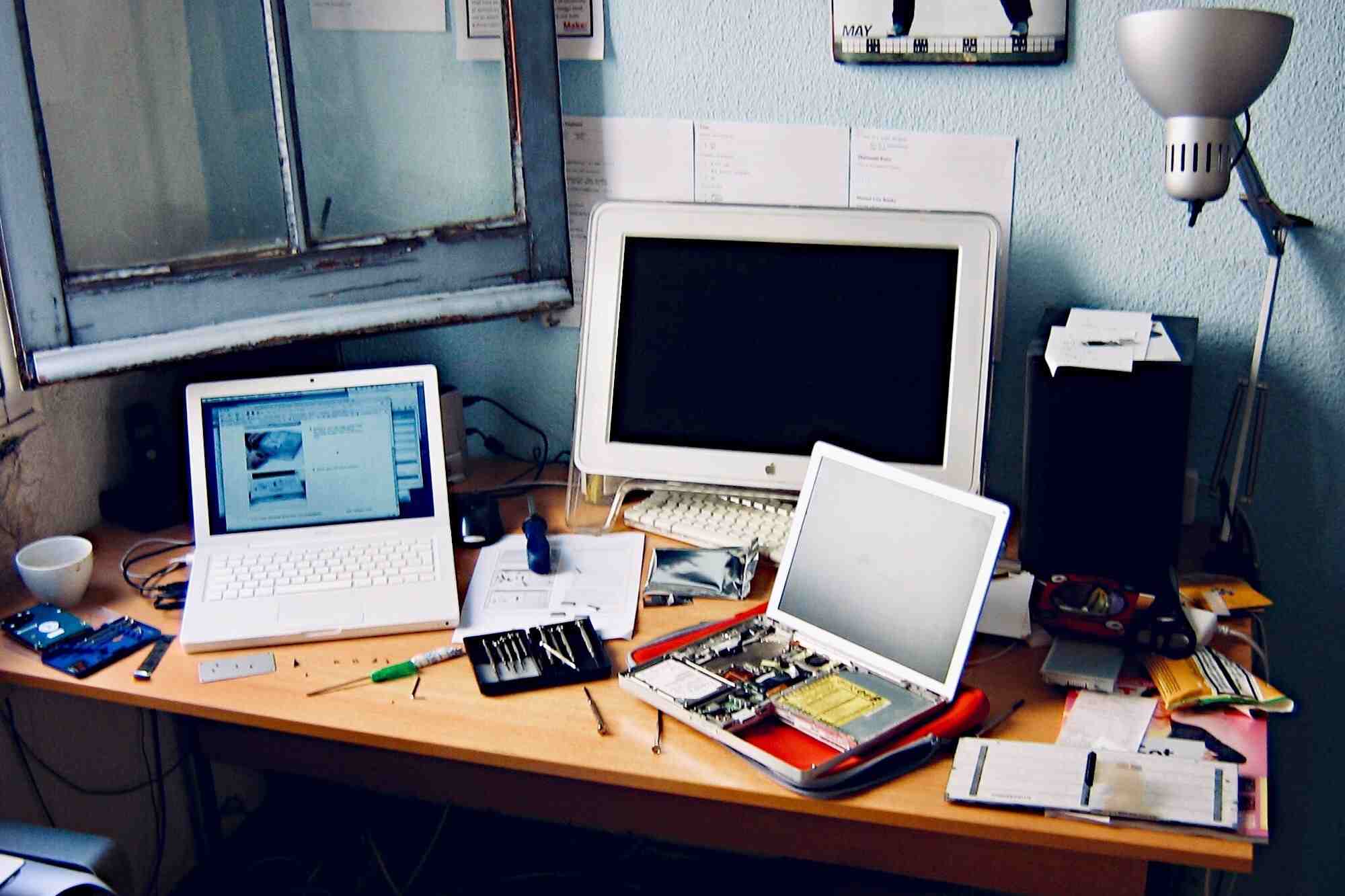

Phòng thí nghiệm tháo dỡ của chúng tôi đang ngập tràn linh kiện iPhone 16, và chúng tôi đã có những trải nghiệm thú vị khi làm việc với chúng. Dòng điện thoại thông minh mới nhất của Apple phần lớn đã gây thất vọng cho các nhà đánh giá công nghệ, những người có ý kiến trái chiều về…

(Phần tiếp theo của bài báo sẽ được viết dựa trên nội dung gốc. Vì chỉ có đoạn đầu của bài báo gốc được cung cấp, nên tôi không thể viết tiếp phần còn lại. Vui lòng cung cấp thêm nội dung để tôi có thể hoàn thành bài báo.)

Ví dụ, nếu phần còn lại của bài báo nói về hiệu năng pin, camera, và các cải tiến khác, tôi sẽ viết tiếp như sau:

…hiệu năng pin, khả năng chụp ảnh và những cải tiến khác. Nhiều người cho rằng sự nâng cấp so với iPhone 15 là không đáng kể, chỉ là những thay đổi nhỏ giọt. Tuy nhiên, qua quá trình tháo dỡ và phân tích kỹ lưỡng, nhóm của chúng tôi đã phát hiện ra một số điểm thú vị về thiết kế bên trong và công nghệ được sử dụng.

Ví dụ, hệ thống quản lý nhiệt của iPhone 16 dường như được cải tiến đáng kể, cho phép máy hoạt động bền bỉ hơn trong thời gian dài. Camera chính cũng sử dụng cảm biến mới, cho chất lượng ảnh tốt hơn trong điều kiện thiếu sáng. Chúng tôi cũng đã tìm thấy một số thành phần mới trong hệ thống ăng-ten, hứa hẹn khả năng kết nối ổn định hơn.

Tuy nhiên, việc sử dụng cùng loại chip xử lý với iPhone 15 đã khiến một số người dùng cảm thấy hụt hẫng. Giá thành cao hơn so với các cải tiến thực tế cũng là một điểm trừ.

Bài phân tích chi tiết về từng linh kiện, cùng với hình ảnh minh họa, sẽ được đăng tải trong những ngày tới. Hãy theo dõi chúng tôi để cập nhật những thông tin mới nhất.

#iPhone16 #MổXẻiPhone16 #PhânTíchiPhone16 #CôngNghệ #Apple #Smartphone #ĐánhGiáĐiệnThoại

Our teardown lab is filled with iPhone 16 parts, and we’ve been having a blast playing with them. Apple’s latest smartphone series has largely underwhelmed tech reviewers, who are mixed on the usefulness of the new dedicated camera button and twiddling their thumbs waiting for Apple Intelligence to drop.

But in our world, it’s a big deal: the iPhone 16 lineup makes three big leaps for repairkind.

First: The adhesive that secures the battery, in the vanilla and Plus models, is this fancy new sticky stuff that can debond when you pass an electrical current through it. That means no more reliance on finicky, brittle adhesive strips, just a consistent, easily repeatable process. It will require a new tool, of course—more on that later.

Second: The 16 Pro battery has a hard steel case instead of a soft pouch, a form factor that looks familiar from the Apple Watch. Every time we’ve heard electronics manufacturers suggest that repairs could be dangerous because of lithium-ion batteries, we point out that the power to make battery repairs safer is in their hands: Hard cell batteries instead of soft pouch batteries won’t get accidentally punctured by a slip of a screwdriver, and so they’re way less likely to catch fire. Since the Pro doesn’t feature the new adhesive, getting the battery out may sometimes require prying, and a hard case will make that process safer. The one model with no battery improvements? The flagship 16 Pro Max.

Third: We’ve lauded the “enter through either the front or the back” design that debuted on the base iPhone 14, but it took two generations for Apple to trickle that innovation up to their pro phones. It’s here on all models now—and it looks like it’s here to stay. Having to remove an expensive, fragile, ProMotion OLED during a repair path isn’t ideal, so being able to avoid it for simple repairs streamlines procedures.

And that’s not even counting iOS 18’s new “Repair Assistant,” which aspires to end the parts pairing software barriers to repair. When we tested it out with the iPhone 15 series earlier this week, we thought it was promising, if not quite ready for prime time. But it worked impressively smoothly on our vanilla iPhone 16: one click to pair and calibrate all components at once, and no bugs to be found.

Announcing FixHub: A New iFixit Tool

Speaking of innovations in repairability, we’re really excited to announce the latest addition to our workbench, the FixHub Portable Soldering Station. This is the mobile soldering iron that we’ve always wanted. It’s lightning-quick: from off to ready to solder in 5 seconds flat. And with the magnetic iron cap, you can make it safe to tuck back into your go-bag without waiting for it to cool off. Preorders are open now.

Fancy New Sticky Stuff

The earliest rumors of new electrically-releasing battery adhesive came back in June, when Wayne Ma at The Information reported that Apple was testing technology to make DIY repair easier.

When adhesive manufacturer Tesa released a video showing their new “Debonding on Demand — Electrical Release” process, we were convinced. We have high confidence that this Tesa technology is adhering the battery.

As soon as Apple’s official iPhone 16 repair manuals dropped (which was actually on launch day, something we love to see), we hustled over to their battery guide, which sure enough described passing 9V through this fancy new adhesive.

So, how does this magical adhesive work? This research paper sheds some light:

In the second scenario, anodic delamination is caused by the oxidation of the surface of the aluminum substrate and migration of Al3+ into the adhesive. This will lead to fast debonding since the substrate layer bonded to the adhesive is no longer supported.

What does this jargon mean? Imagine an Oreo cookie with a thick layer of double-stuf creme. You figured out that if you dip just the bottom cookie in some milk and twist the cookie apart, the filling will always stick to the top cookie.

Similarly, when we zap the adhesive, the current oxidizes the negative/anode mating surface and loosens the adhesive from it. The adhesive “filling” between the battery and the frame will then stick to whichever surface that’s connected to the positive terminal.

Trial Run of Our Next FixHub Tool

When the time came to crack open the new phones, we were ready with a prototype of our new iPhone battery repair tool: a USB-C cable on one end, alligator clips on the other. We plugged it into our FixHub Power Station, clipped the ground wire to a nearby screw, and attached the red wire to a silver tab next to the battery.

Our cable was set up to deliver 12V, and since Tesa suggested that their adhesive would release in 60 seconds at 12V, we waited a minute: Sure enough, the battery lifted out with no force, and the case underneath was almost residue-free (though the battery side remained tacky). You’ll probably still want to take a pass with isopropyl alcohol before you put a new battery in, but you won’t have to scrape out adhesive strip remnants like in iPhones of yore.

One of the biggest problems with the current stretch-release adhesive strips—the ones still used in the 16 Pro and Pro Max—is that they get more and more brittle over time. In older phones, repair techs essentially expect that they’re going to have to apply a solvent under the battery to get the adhesive to disengage—not a huge deal, but depending on the solvent and how careful you are with application, it can damage other internal components. Only time will tell how this new adhesive ages; Apple’s own repair manual suggests that the adhesive may take longer to disengage over time. They say you can use up to 30V to trigger the electrical release. We tried releasing our battery at several different voltages. At 20V, the battery released in about 5 seconds. At 5V, it took a tad over 6 minutes.

The adhesive sits inside a well in the frame, specially machined to create ridges and rough surfaces for the glue to adhere to. A close up under Evident Scientific’s microscope really brings this simple but beautiful structure to life.

This Phone Needs a New Tool. Is That a Repairability Problem?

The last time iPhone repair required a brand new tool—when Apple began sealing phones with their proprietary five-pointed screw, the pentalobe—we raised a fuss. At the time, nobody outside official Apple repair shops had access to the driver, which effectively blocked repairs until we reverse-engineered it. This is pretty different. Any hardware store around the world will sell you a set of alligator clips and a 9V battery, at a reasonable price.

Everyone fixing one of these phones is going to need a power supply of some kind. Apple’s 9V battery solution is perfectly fine, but USB-C can also output the needed power and is in some cases more convenient (9V batteries have fallen out of favor). Good news: we’re already working on a ruggedized version of our prototype to include with our battery repair kits.

Is It Reversible?

If we connected the 9V in reverse, would that rebond the adhesive? Nope. The adhesive remained ungrippy. The reverse polarity did have an effect: when we reverse-zapped a new phone, the zap released the battery, but the adhesive residue stuck to the frame instead of the battery. Before that, a positive zap consistently left the residue on the battery. If you’re trying this at home, be sure to get the polarity right so you have less residue to clean up on the frame!

It doesn’t seem like this adhesive is intended to be multi-use. We’re guessing that Apple will sell batteries with the new adhesive already applied (the repair manual describes “peeling the pink release liner” off the adhesive).

Easy Battery Repairs Matter

There was a time when cell phone battery replacements hardly deserved being called a repair—you’d pop the back cover off with your thumbnail and stick in a new battery. Fairphone has proven that this is still possible in the form factor of a modern smartphone, with an IP55 rating.

But until the industry goes the way of Fairphone (or chooses that’s where they want to innovate), battery replacements will remain the repair most worth talking about. Batteries are consumables. They’ll eventually wear out, no matter how durable the rest of your phone is. Extending a phone’s life by a year saves about 100x the phone’s weight in CO2 emissions, and easy battery replacements are a necessary part of that lifespan extension.

Some people have speculated that the new adhesive is aimed at helping Apple comply with new European Right to Repair regulations that passed recently, but we don’t think that’s what’s going on here. There are two regulations that address battery repairs: Ecodesign for Smartphones and the new Battery Regulation, each with slightly different requirements for compliance, both requiring easily removable batteries. Europe will probably enforce one or the other. The Joint Research Commission has suggested that Ecodesign will likely supersede, but it’s not yet settled.

Regardless, in either case, we don’t believe the changed battery adhesive affects compliance—stretch-release adhesive and electrical-release adhesive under a battery seem to be equally compliant. However, display removal is a sticking point for both regulations: The iPhone 16 display removal is not compliant with the Ecodesign Directive because of the use of pentalobe screws, and it’s not compliant with the battery regulation because it requires heat for entry. If Apple could use this new voltage-release adhesive to open the phone, that might get them compliant with the Battery Regulation.

Improved Thermal Handling of AI Workloads

How well the iPhone can dissipate heat has always mattered: When the processor gets too hot, it has to throttle down and reduce performance. In this new world of AI, with on-device machine learning models, performance is going to matter more than ever. Faster models are more intelligent and can give you better suggestions or photo enhancements.

Apple has significantly changed up their approach to dissipating heat from the main A18 processor with a new, ferrous heat sink. In this photo it looks like an EMI shield, but it’s actually a solid block of material. This sink sits inside the mainboard sandwich, soldered to the inside of the RF half of the logic board—which has an L-shaped footprint, similar to iPhones past and the 15 Plus from last year. Thermal paste transfers heat from the A18 to this sink.

Intriguingly, this heat sink only covers about half of the A18 SoC. If the alignment of the die markings match Apple’s marketing photos, then the heat sink is over the Neural Engine, Apple’s machine learning hardware. The more efficiently they can run their Neural Engine, the better it will work. These improvements will enable the iPhone to run at maximum performance longer than previous designs.

Is the Camera Control Button … a Button?

Aside from the delayed Apple Intelligence, the feature that’s got everyone talking in this lineup is the new dedicated camera button. Yes, it does physically actuate. Yes, it’s a button. But there’s more to it than that. When we pulled it out, we discovered that it’s got its own tiny integrated circuit.

Unfortunately, the button seems to be laser-welded to the frame. Buttons in past models featured a latch mechanism that made them fully replaceable and repairable. Now, if the button malfunctions, you’ll have to replace the whole frame. The welds appear unnecessary, except to attach the button and its IC to the frame. There’s a new “enclosure” component in the service history of the phone, and we confirmed it’s tracking this IC—when we swapped out a button, “enclosure” popped up in the history.

Chips enable parts pairing, the software barrier to repair that has increasingly plagued Apple products. But since the new Repair Assistant mode worked flawlessly for us on the iPhone 16, a new serialized part is less of a red flag today than it was before.

The spot where the button slots into the frame previously held a 5G mmWave antenna in the iPhone 15 (and every model back to the 12). Now there seems to be just one mmWave antenna left, sitting up against the camera assembly. Will that affect the phone’s signal strength?

We also noticed this interesting flex cable epoxied onto the bracket holding the button in place. This is likely the “force sensor”—a strain gauge that converts tiny amounts of deformation into changes in resistance. The iPhone uses this to sense half-presses before the button actually clicks.

Settling the Score

Last year, we awarded the iPhone 15 a lowly four out of ten, primarily due to the real-world complications that parts pairing causes. This year, Apple has changed their tune. Accordingly, we’re changing ours.

Let’s start with the basics: Apple’s repair manuals are well written, well above the average we see from other manufacturers, and it’s awesome (like, really cool!) that Apple had them ready for launch day. Our only real gripes are a lack of schematics for board-level repairs, and missing repair procedures for the charge port or any buttons. Everything else looks great.

Repair parts aren’t on sale yet, but if Apple matches what’s already available on the 15-series, they’ll get quite a bit of credit there—mostly a good offering with a few omissions (no charge ports, buttons, or enclosure, for instance) and a display assembly that’s too pricey to be an attractive repair option for most people.

The new battery procedure is the design highlight. We repeatedly deactivated the adhesive with a variety of tools and timings, and the procedure seems very robust. We really like that you don’t need an expensive proprietary tool for this: You could rig up any 9V battery with whatever length of wire you’ve got lying around, and you’re set. We’d still prefer screws or some other fastener that’s easier to reverse—this will require cleanup/prep before installing a new battery (which presumably comes with fresh adhesive pre-applied, otherwise folks will have to get creative). And the adhesive supplier will need to make this glue available to the repair market. Still, this is a really cool innovation.

The dual-entry design, first introduced on the 14 series, remains very elegant. Once inside, lots of components are independently accessible with little to no additional disassembly. The layout is smart, prioritizing access to critical repairs like battery and camera replacement. In past models, it was normal to see, for example, battery pull tabs blocked by a Taptic Engine, which was blocked by a speaker, which was blocked by a big grounding bracket—all of that having to come out in sequence. The 16’s design offers independent access to the battery, the speaker, the Taptic Engine, cameras, display, back cover, and so on. It’s really thoughtfully laid out.

The largest remaining obstacles to repair: Apple continues to use a variety of fussy screw types. The display and rear panel adhesive requires heat to get inside. But we’re beyond pleased that Repair Assistant worked effortlessly, which removes our biggest complaint about the last few models of iPhone.

The iPhone 16 earns a respectable 7 out of 10, a significant upgrade from last year’s model.

Source link Xem chi tiết và đăng ký[featured_image]